From biocidal coatings to medicines: A nanocomposite sting for microorganisms

28 January 2026

EurekAlert!: [https://www.eurekalert.org/news-releases/1114572]

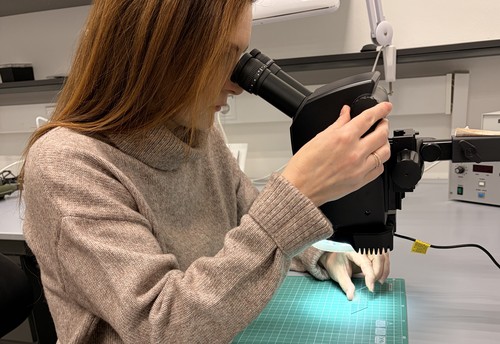

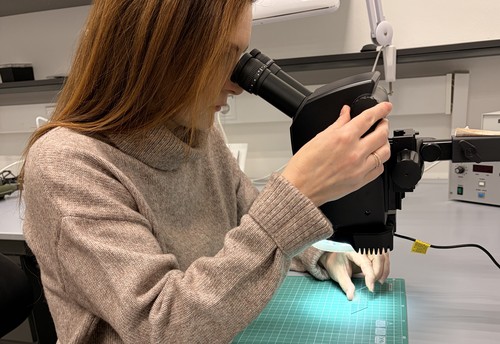

Magdalena Laskowska from the Institute of Nuclear Physics of the Polish Academy of Sciences in Cracow examines a glass plate covered with a layer of B-STING material. (Source: IFJ PAN)

A surface capable of responding to chemical signals generated by microorganisms and automatically producing biocidal substances – this is not a futuristic vision, but a description of how the B-STING silica nanocomposite works. The new material, developed at the Institute of Nuclear Physics Polish Academy of Sciences in Cracow, acts as a nanofactory of reactive oxygen species, activating itself only when necessary.

Can a hospital treat patients? The question seems trivial until we clarify that we are referring to the building itself and its standard fittings, not the institution, doctors or medical equipment. So, could a hospital window kill bacteria? Could door handles, handrails and light switches disinfect themselves? The answer is yes, if they are covered with a thin layer of a carefully designed silica nanocomposite, in whose mesopores molecular factories of reactive oxygen species are placed. Just such a material, called B-STING (Biocidal Silica-Templated Immobilised Nano-Groups), has been designed, manufactured and characterised by scientists from the Institute of Nuclear Physics Polish Academy of Sciences (IFJ PAN) in Cracow.

“When we use nanoparticles of, say, gold or silver for biocidal purposes, they have to interact directly

with microorganisms. Our material is the result of a decade of work on a radically different approach

to the issue. It is not in itself a biologically active substance. However, what it is, is a

nanofactory that produces reactive oxygen species that are lethal to microorganisms and effectively

penetrate the cell membranes of bacteria and fungi,

” says Dr. Magdalena Laskowska (IFJ

PAN), the first author of an article published in the renowned scientific journal Applied Surface Science.

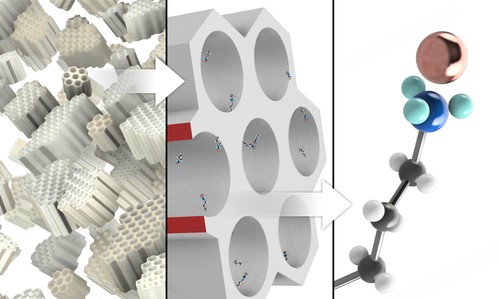

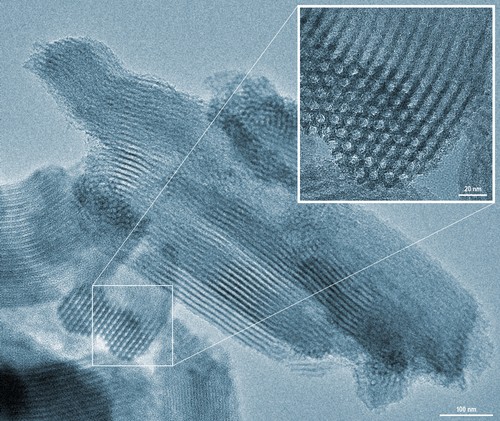

The structural foundation of the new material is silica with cylindrical mesopores eight nanometres in diameter, spatially arranged in a layer with hexagonal regularity, resembling a honeycomb in appearance. The surface area of a flat sample covered with a 100-nanometre-thick layer increases almost 80-fold. On the expanded surface, inside the pores, functional groups containing single metal atoms, which in the case of the samples in question were copper, are attached at appropriate distances from each other using propyl bridges. In a material constructed in this way, the functional groups are protected by the walls of the mesopores, which guarantees high durability. At the same time, each copper atom has the ability to act effectively as a single-atom catalyst.

“Gold and silver nanoparticles, currently popular in various applications, are agglomerates consisting

of many thousands of atoms. Most of them are shielded by their neighbours and are therefore

unable to perform their intended role. Meanwhile, the precise architecture of our material ensures

that each metal atom has access to its surroundings and can catalyse the production of reactive

oxygen species from water and oxygen contained in the air penetrating the mesopores. As a result,

B-STING does not need any external trigger, such as light or ultrasound, so it can work even in

the dark,

” notes Dr. Lukasz Laskowski, professor at the IFJ PAN.

It should be emphasised that, unlike many types of nanoparticles which wear out or require activation, the copper centres in the new material catalyse the production cycles of reactive oxygen species without the need for permanent chemical restructuring. In other words, the material does not need to be regenerated and works as long as it has access to oxygen and water.

Thanks to cooperation with the Medical University of Lublin, it was possible to conduct more extensive research into the biocidal effect of samples coated with the new nanocomposite. It turned out that coatings made from it kill a number of pathogenic bacteria, fungi and even viruses. At the same time, tests carried out on human fibroblasts proved that it is safe for them, which came as a huge surprise to the researchers. In practice, this means that biocidal substances are produced by the new material only when necessary. The material does not detect bacteria directly, but reacts to changes in the environment caused by them – such as a drop in pH, the presence of sulphur compounds (thiols) or local fluctuations in oxygen availability – and adjusts the composition of the reactive oxygen species it produces accordingly. Importantly, the production of disinfectants is not constant, and when there are no microorganisms nearby, its profile changes. Details of the outlined mechanism cannot be disclosed at this time due to the patent process.

“If further research does not reveal any negative effects of introducing our material into the body, it

could even become a component of medicines in the future – as a substance that is at least potentially

more effective than antibiotics in combating a wide range of microorganisms,

” says Prof.

Laskowski.

Years of research are necessary before therapies involving the use of drugs containing B-STING silica nanocomposite become available. In the meantime, biocidal coatings made from this material can already be widely used. They are safe, durable (mechanically similar to glass), resistant to dirt (dirt particles are larger than the pores and do not block the flow of air to the catalytic centres), and maintain a constant readiness for on-demand production, activating automatically in response to changes in the chemical environment. These coatings can be applied to various materials – especially polymers, metals and glass – as well as to objects with complex shapes. In the long term, the lack of a trigger and long-term operation also allow for intrabody applications, in the form of coatings on implants or dental fillings.

Researchers from the IFJ PAN also emphasise the economic aspects of producing these coatings. Even very thin layers are effective (after applying the material to glass, there is no significant change in transparency), the small amounts of precious metals used in production, the price of copper being significantly lower than the price of silver or gold, and the moderate cost of the compounds necessary for production suggest that the production of coatings from the new silica nanocomposite will be economically viable.

[PDF]

Contact:

Dr. Magdalena Laskowska

Institute of Nuclear Physics, Polish Academy of Sciences

tel.: +48 12 399 8065

email: magdalena.laskowska@ifj.edu.pl

Dr. Łukasz Laskowski, Prof. IFJ PAN

Institute of Nuclear Physics, Polish Academy of Sciences

tel.: +48 12 399 8263

email: lukasz.laskowski@ifj.edu.pl

Scientific papers:

„Mesoporous silica-based nanocomposite surfaces with ROS-generating copper phosphonate functional groups in the fight

against dangerous microorganisms”

M. Laskowska, M. Doskocz, A. Karczmarska, K. Pogoda, A. Olender, E. Gumbarewicz, A. Bogut, M. Gagoś, A. Stepulak,

W. Dąbrowski, Ł. Laskowski

Applied Surface Science 720, Part A, 165228, 2026

DOI: 10.1016/j.apsusc.2025.165228

Images:

Magdalena Laskowska from the Institute of Nuclear Physics of the Polish Academy of Sciences in Cracow examines a glass plate covered with a layer of B-STING material. (Source: IFJ PAN)