Complexity of crystallization amazes physicists

27 June 2022

EurekAlert!: [https://www.eurekalert.org/news-releases/957132]

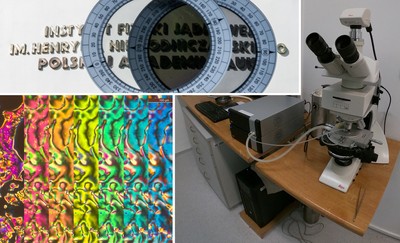

A better understanding of the complexity of crystallization processes occurring in liquid crystals brings us closer to a new generation of liquid crystal displays. (Source: IFJ PAN)

On the one hand, softly organized and ordered, on the other hand, flowing like water or honey – this is the dual nature of liquid crystals. Scientists from the Institute of Nuclear Physics of the Polish Academy of Sciences took a detailed look at one of the aspects of liquid crystals: the crystallization processes. The latest research shows that in the case of certain types of liquid crystals, these processes not only occurs when they are cooled and heated but are also surprisingly complex in nature.

Liquid crystals are versatile in use. They can be found in liquid crystal displays (LCDs), which use not single liquid crystal compounds but mixtures of them. It turns out that glass-forming materials are more useful when designing new generation LCD displays, as they are better suited as components of mixtures than easily crystallizing compounds. The substances that create chiral smectic phases are especially promising for the LCD display technology, because thanks to them it is possible to construct devices with a short switching time, high contrast and wide color scale.

“First: the recognition. In order to determine whether a given liquid crystal is suitable for specific applications, basic research should be carried out using complementary experimental methods to learn about the physicochemical properties, structure and dynamics of the compound,

” explains Dr. Eng. Anna Drzewicz from the Institute of Nuclear Physics of the Polish Academy of Sciences (IFJ PAN) in Cracow, and Dr. Eng. Małgorzata Jasiurkowska-Delaporte (IFJ PAN) adds: “... and also to check whether it crystallizes, or whether it is capable of forming a glassy state.

”

Crystallization is a complex process including nucleation (i.e. the formation of nuclei) and crystal growth that is controlled by both kinetics (i.e. molecular mobility) and thermodynamic driving forces. The phenomenon of crystallization is usually associated with cooling of a given material. However, if the compound under study is cooled down sufficiently quickly, it has a chance to vitrify. How fast the cooling rate is supposed to be depends on the nucleation rate, which is an individual feature of the substance. The glassy state is related with the slowing down (or even freezing) of stochastic motions.

“The game of 'Statues' comes to mind here (it has a different name depending on the region). The participants move freely, but on the leader's command they must immediately stand still in the pose they have just performed,

” says Dr. Drzewicz.

The 3F5HPhH7 liquid crystal, which is the subject of the research, was obtained at the Institute of Chemistry of the Military University of Technology in Warsaw. Scientists from the IFJ PAN found that it forms several chiral smectic phases (SmC*, SmCA* and SmXA*). Slow cooling of the sample resulted in its crystallization, and during fast cooling it showed a greater tendency to vitrify to the SmXA* phase than to a crystalline form. Additionally, as a result of sample heating (after its fast cooling), the phenomenon of the so-called cold crystallization occured. This type of crystallization emerges during heating of a previously vitrified disordered thermodynamic state. The detailed characteristics of the 3F5HPhH7 liquid crystal can be found in the article published in the prestigious physicochemical journal Physical Chemistry Chemical Physics.

In the next step, scientists from the IFJ PAN took a closer look at both crystallization processes of the 3F5HPhH7 compound.

“We wanted to check the kinetics of crystallization both during cooling and heating of the compound and to determine whether we are able to control or modify these processes by the rate of temperature change,

” says Dr. Jasiurkowska-Delaporte.

The methods of differential scanning calorimetry (DSC), broadband dielectric spectroscopy (BDS) and infrared spectroscopy (FTIR) were used to monitor the crystallization kinetics. These techniques measure very precisely the response of a sample to the action of various external factors, providing complementary information about its state and the current processes, what is necessary for understanding the phenomena. The results, recently published in the journal CrystEngComm, shed new light on the mechanisms behind the crystallization processes of 3F5HPhH7.

The Avrami model was used to analyze the crystallization kinetics. The obtained results showed that the crystallization during sample cooling is controlled by nucleation and takes place through the three-dimensional growth of crystallites (the dimensions of growing crystallites are indicated by the value of the so-called Avrami parameter).

However, the analysis of the kinetics of cold crystallization brought surprising results. Under non- isothermal conditions, the process depends on the rate of heating of the sample. When the temperature rises slowly, the cold crystallization is mainly dependent on molecular diffusion, and under rapid heating conditions – on nucleation. The rate of temperature changes turned out to be significant also in the case of cold crystallization tested under isothermal conditions. When the sample is quickly heated to the cold crystallization temperature, a two-step process emerges, with each step having a different dimensionality of the resulting crystallites. Slow heating of the compound changes the nature of the cold crystallization from a two-step process to a one-step process.

Interestingly, both the two-step and one-step isothermal cold crystallization processes are primarily controlled by the rate of diffusion. This is in contrast to the faster melt crystallization which is solely governed by thermodynamics.

“We are pleased with the fact that all the experimental methods used provided consistent information, which allowed us to recreate the course of the crystallization processes in detail and proved the correctness of using complementary methods to study liquid crystals,

” sums up Dr. Drzewicz.

“The 3F5HPhH7 compound shows how diverse the crystallization process can be and how it depends on the rate of temperature change. This knowledge fits perfectly with the current challenges faced by condensed-phase physics and in particular soft matter,

” emphasizes Dr. Jasiurkowska-Delaporte.

The obtained results have great value but they do not exhaust the subject matter. The in-depth understanding of the possibilities of controlling the crystallization process of glass-forming materials is a stimulus for continuous research, also in the context of potential applications.

[PDF]

Contact:

Dr. Eng. Anna Drzewicz

The Institute of Nuclear Physics, Polish Academy of Sciences

tel.: +48 12 662 8063

email: anna.drzewicz@ifj.edu.pl

Dr. Eng. Małgorzata Jasiurkowska-Delaporte

The Institute of Nuclear Physics, Polish Academy of Sciences

tel.: +48 12 662 8481

email: malgorzata.jasiurkowska-delaporte@ifj.edu.pl

Scientific papers:

„On relaxation and vibrational dynamics in the thermodynamic states of a chiral smectogenic glass-former”

A. Drzewicz, M. Jasiurkowska-Delaporte, E. Juszyńska-Gałązka, A. Deptuch, M. Gałązka, W. Zając, W. Drzewiński;

Physical Chemistry Chemical Physics, 24, 4595-4612, 2022;

DOI: https://doi.org/10.1039/d1cp05048f

„Insight into cold- and melt crystallization phenomena of a smectogenic liquid crystal”

A. Drzewicz, E. Juszyńska-Gałązka, M. Jasiurkowska-Delaporte, P. Kula;

CrystEngComm, 24, 3074-3087, 2022;

DOI: https://doi.org/10.1039/d2ce00224h